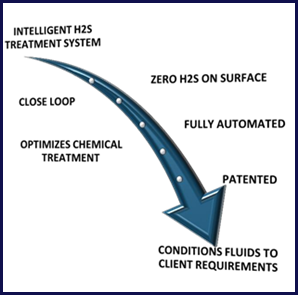

Our Intelligent H2S Treatment system is an AUTOMATED, CLOSED LOOP AND MOBILE flow back fluid treatment system. It ensures zero H2S (hydrogen sulphide) is discharged on surface. By mitigating H2S on surface, personnel are not at risk due to process upsets and the fluid can be stored safely.

The System optimizes chemical treatment and safeguards against H2S fluctuations by real time automated sampling and testing and instantaneous feedback to the dosing pumps. It also reduces residence time for the chemicals to condition the fluid.

This H2S treatment system can also condition the fluid by:

- Viscosity Reduction

- Breaking of Emulsions

- Fluid Neutralization

- Gas Hydrate Treatment

The fluid conditioning is done as per client requirement.

Key features of the system are:

- The System consists of chemical techniques to minimize equipment and ensure the process equipment is mobile. An innovative, new oil soluble H2S Scavenger is used based on its excellent performance. The product was designed on a molecular level.

- It is fully automated. The whole process is monitored and controlled from a Control Cabin.

-

- The Operator is working from a Safe Area and is not subject to exposure risks present outside.

- Tank Levels and Oil/Water Interface are monitored from the Cabin

- The Chemical Injection Pumps and Valves on tanks can be shut down from the Control Cabin in case of Upset Conditions.

- It optimizes Chemical Treatment

-

- Real time feedback from the H2S Sensors to the PLC controls the rate of chemicals injected by the Programmable Pumps, thus optimizing chemical usage and reducing chemical costs in the long term.

- Optimization is done automatically by the system. It is therefore intelligent.

- The System houses all the sensor probes and ensures efficient fluid homogenization and enhanced chemical performance.

-

- Scavenging of H2S and Viscosity Reduction of Oil take place with reduced treatment time.

- The Sensors Optimize Chemical Treatment.

- The Secondary Separators, (fitted with Interface Level Gauges, Recirculation loop and a programmable pump) provide:

-

- Residence time for Separation of free water

- Testing of Crude Oil to ensure it has been conditioned for ideal flaring

- Storage for Upset Conditions.

- The Gas Scrubbers strip H2S from the both the separator and bulk storage tank gas lines. Gas scrubbers are available for working pressures from 150psig to 1200psig